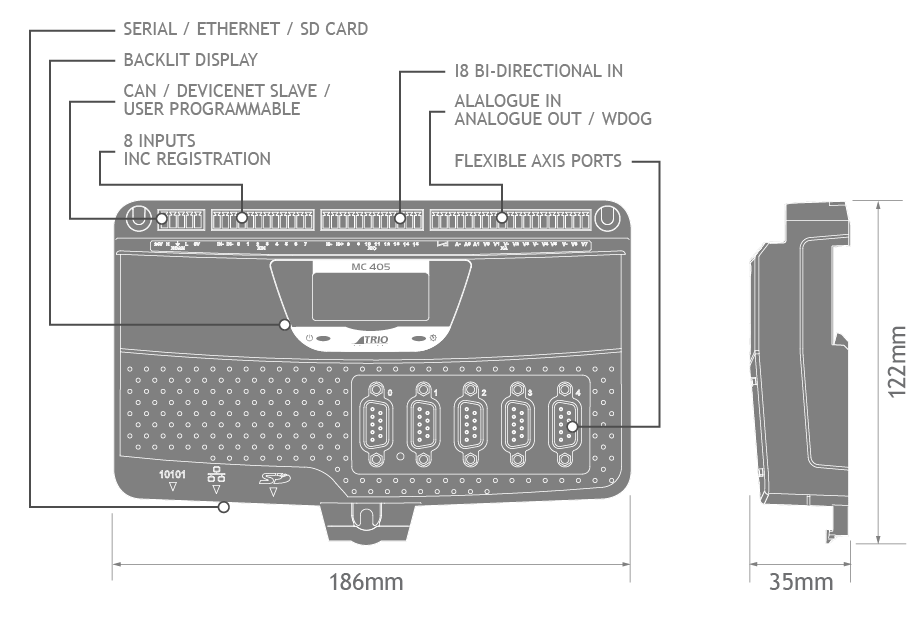

MC405

in 2 variants

MC405

P826 (stepper) | P827 (servo)

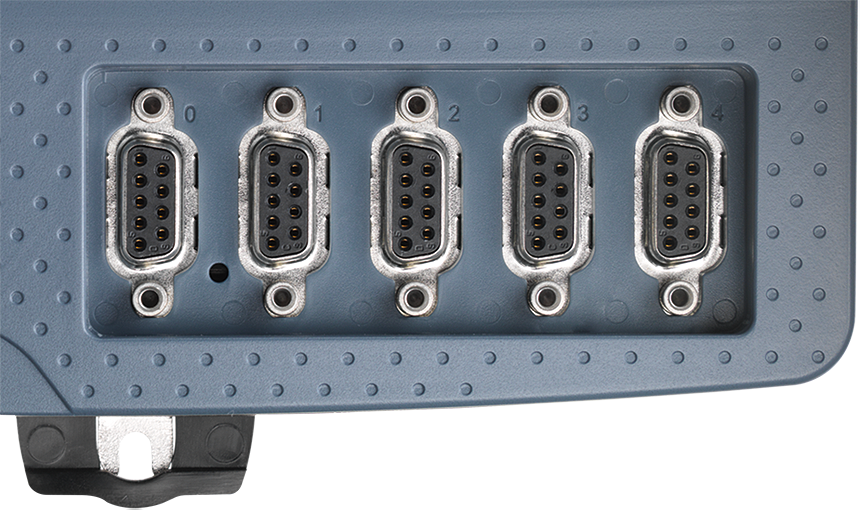

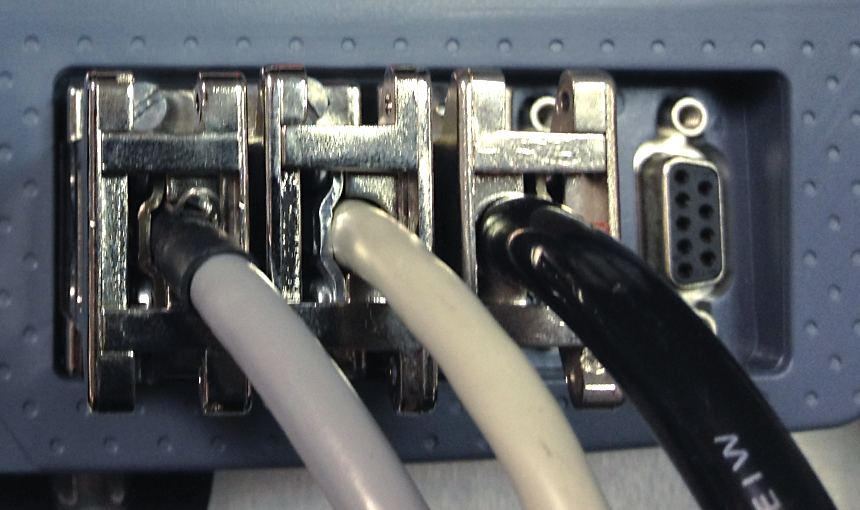

The MC405 is a high specification Motion Coordinator using a high performance ARM11 processor, with

five flexible axis ports and four Voltage outputs.

MC405s loaded with firmware 2.0311 and later will show a performance improvement of at least 50%, will run programs faster, and have better performance with communications to HMIs and PCs compared to earlier versions. This upgrade will allow the very popular MC405 to enjoy a life extension alongside newer products such as the MC404-Z.

Highlights

- Advanced 4 Axis Closed Loop Servo / 5 Axis Pulse Direction

- Linear, Circular, Helical and Spherical Interpolation

- Flexible CAM shapes, Linked Motion

- Biss, EnDAT and SSI Absolute Encoder Supported

- Hardware Linked Outputs for Camera / Laser Control

- Ethernet-IP / Modbus TCP / Ethernet Interface Built-In

- 125 – 2000 µsec Selectable Servo Update

- Precise 64 bit Motion Calculations on ARM11 Processor with VFP

- IEC 61131-3 Programming

- Multi-tasking BASIC Programming

- Text File Handling

- Robotic Transformations

- Micro SD Memory Card Slot

- CANopen I/O Expansion

- Backlit LCD display

- RoHS, UL Listed, CE approved

Flexibility

The flexible axis ports can be configured in software as feedback devices or pulse direction outputs. As outputs they can be used as pulse and direction with stepper or servo drives or they can operate as a simulated encoder output. When configured as feedback they can be either incremental encoder input or one of three popular absolute encoder types; SSI, Tamagawa, Endat or Biss. Any feedback axis with a voltage output can be used to form a closed loop servo.

Plug & Program

The built-in Ethernet port allows programming and connection of common HMI and PLC protocols directly to the MC405.

User programs can be written in Trio’s established multi-tasking TrioBASIC language using the powerful Motion Perfect application development software making complex motion easy. Also available as an option is the industry standard IEC 61131-3 languages allowing fully functional PLC programming system.

Connectivity

The MC405 is available in 2 different axis configurations. Both models feature a total of 16 axes in software. Any axes not assigned to built-in hardware can be used as a virtual axis. Every axis can be programmed to move using linear, circular, helical or spherical interpolation, electronic cams, linked axes and gearboxes.