Motion-PLC

Motion & Logic…

A New class of Controller…

Trio's Motion-PLC incorporates advanced motion functions alongside the simplicity of a PLC; a true paradigm shift in the world of motion and factory automation.

Contact us for more information

MCS 30

Flexible Machine Motion Coordinator

Find Out More

Ideal for simple machines...

Example: Point to point operations.

Low axis count.

IEC 61131-3 languages.

MCS 40

Flexible Machine Motion Coordinator

Find Out More

Ideal for Stand-Alone sub-machines...

Example: Gantry machines.

Low axis count.

EtherCAT axes.

Simple digital and analogue I/O.

MCS 50

Flexible Machine Motion Coordinator

Find Out More

Ideal for larger stand-alone machines...

Example: Glue laying machines.

Medium axis count.

EtherCAT axes.

High speed counter, registration inputs.

PTO, position controlled outputs.

Advanced motion features.

Auxiliary encoder input.

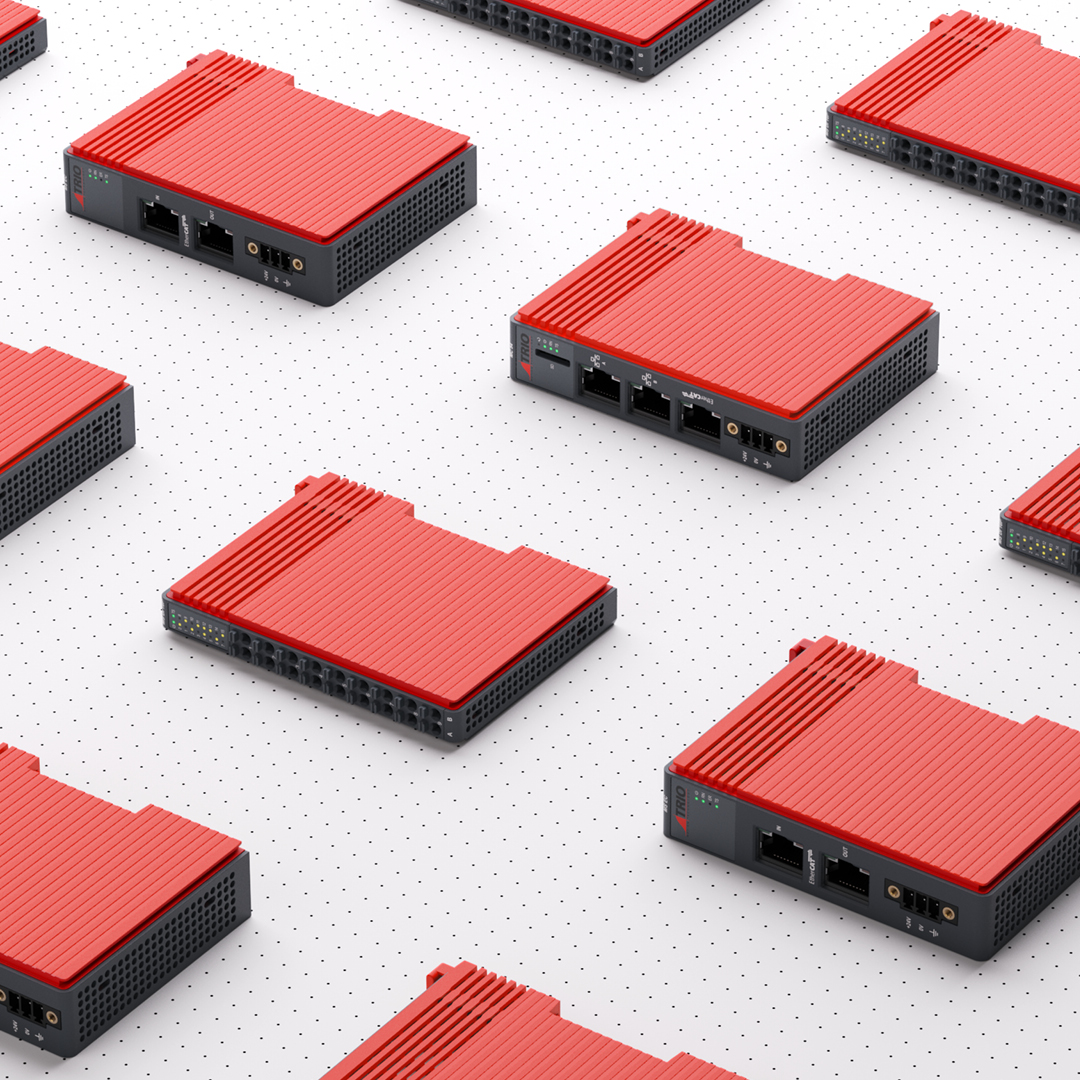

MCS I/O

Compact EtherCAT I/O Expansion

Find Out More

MS I/O System (Motion-PLC I/O expansion) offers a compact, robust, high performance I/O expansion system.

High performance, flexible topology.

Local expansion up to 16 slices.

Front face insertion and removal.

Any combination of digital and analogue slices.

Bringing Motion-PLC to market

Design and functionality

Trio commissioned Smallfry to design and engineer its latest, landmark product, the Motion-PLC. Packed full of new features and technology, the new product range delivers Trio’s advanced motion control performance with the functionality and simplicity of a PLC.

To achieve such a compact yet powerful package, Smallfry worked closely with Trio’s electronics team whilst engineering the casing in order to maximise PCB footprint without compromising its structural integrity, appearance, and product features.

A modular front-loading slice expansion system enables engineers to easily swap out and expand modules as needed. To achieve this, the team developed a new BUS electrical connector, integrated into the Trio red side panel, providing a repeating colour accent visible across the front of the system when installed together.

A modular, adaptable system

A defining feature of the product range is the incorporation of a modular front-loading slice expansion system - MS I/O. This enables users to tailor system configurations to their needs whilst also providing the flexibility to expand and service modules up to 16 I/Os.

Achieving this required a total rethink of the entire approach. Smallfry developed a new BUS electrical connector, integrated into the striped side panel, that enables modules to instantly connect when installed together guided by the tightly controlled sliding rails. The last piece in the puzzle was to develop a custom DIN rail latch that would reliably lock and unlock products in place.

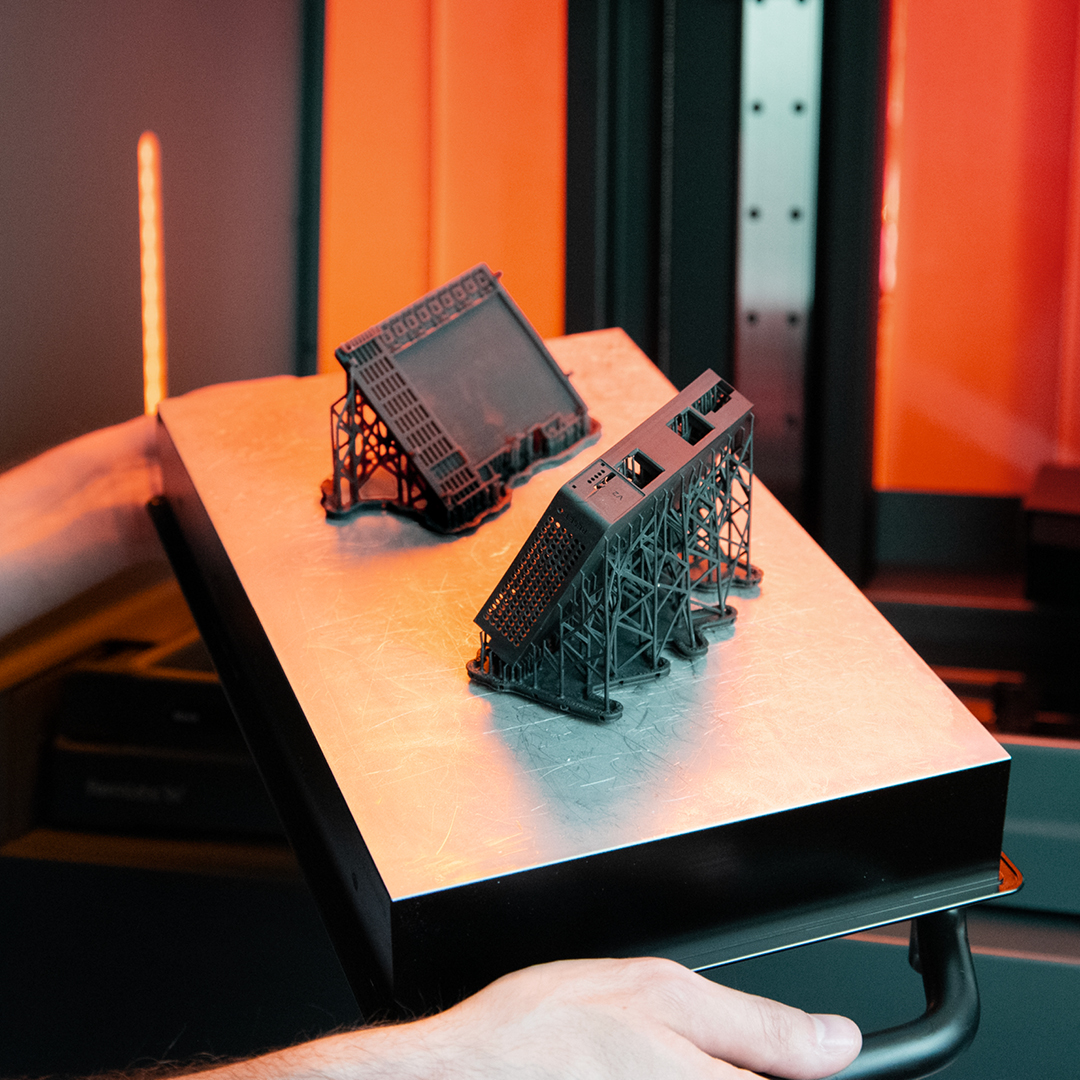

To achieve this, the latch was engineered with a compliant mechanism that enables it to actuate on both sides of the DIN rail, translating upward motion into downward. Using 3D CAD and Smallfry's in-house rapid prototyping, the team produced parts that simulated injection moulded components without the need for upfront tooling investment. This enabled the team to explore, evaluate, and refine a range of ideas quickly to hone in on the final solution, ready for tooling release.

From design to production

Smallfry worked with us to design and engineer the product from concept though to production. The hands-on approach, utilising our in-house prototyping capability, ensured that every detail was captured and tested along the way.

Moving into production, Smallfry created a complete 3D and 2D data pack ready for injection moulding. Once parts had been tooled, their engineers worked alongside the manufactures to review off-tool samples, identify issues as they arose, and ensure that any tooling adjustments targeted the root cause of issues.

Thanks to Smallfry for use of text and images in this story.